Cross-border trucking procedures for compliant operators

Both operators and their drivers need to be acutely aware of their responsibilities and obligations when crossing borders in southern Africa. This guide should provide some clarity

Responsibilities

It is the responsibility of the operator or carrier to ensure that:

• The vehicles are roadworthy and in

possession of a Certificate of Fitness

• Each vehicle has been registered with the Cross Border Road Transport Association (CBRTA) and is in possession of cross-border permit.

• If transporting dangerous goods (DG) or hazardous chemicals (Hazchem), the vehicle is registered as a DG operator and the Operators Card or disc is displayed on the windshield of the vehicle. Also that: *

The vehicle is hazchem compliant;

* The driver is correctly trained and Hazchem certified;

* The driver is in possession of his (category D) Professional Drivers Permit (PrDP);

* His/her licence is free of endorsements.

• The vehicle does not exceed the permissible axle masses (DO NOT OVERLOAD!)

• All drivers receive regular medical examinations, for example, every six months.

• The load is secured before dispatching the vehicle.

• Pre-trip and vehicle inspections are carried out prior to the vehicle’s departure.

• The driver is in possession of the required cross-border documentation for the load (Customs manifest, Consignment note, Commercial invoice, etc.)

• All drivers are made aware of cross-border operating procedures.

It is the responsibility of the driver to ensure that he or she:

• Is fit to drive – and has had a medical examination in the last six months;

• Is in possession of a valid PrDP;

• Has been adequately trained for the job at hand (and that in the case of Hazchem loads has been Hazchem certified);

• Ensures the load is secured before departing.

• Is in possession of the required

cross-border documentation for the load;

• Is familiar with the cross-border operating procedures; and

• Carries out pre-trip and vehicle inspections prior to the vehicle’s departure.

Documentation required for South African import

The standard set of documents includes:

• Customs road manifest

• Consignment note

• Commercial invoice

• Packing list

• Importer’s written clearing instructions

Supporting documents include:

• Certificate of Origin – SADC, COMESA or DA 59

• Import permit

• Worksheets

• Veterinary, health or agricultural permits or certificates

• Quota permits

• Trade agreement licences

• Rebate permits

documentation required for South African export

The standard set of documents includes:

• Customs road manifest

• Consignment note

• Commercial invoice

• Packing list

• F 178 – bank clearance for goods valued at R50 000 or more

• Exporter’s written clearing instructions

Supporting documents include:

• Certificate of Origin – SADC, COMESA or SAD 500

• Export permit

• Worksheets

• Veterinary, health or agricultural permits or certificates

• Quota permits

• Trade agreement licences

• Rebate permits

Correct loading procedures for heavy vehicles

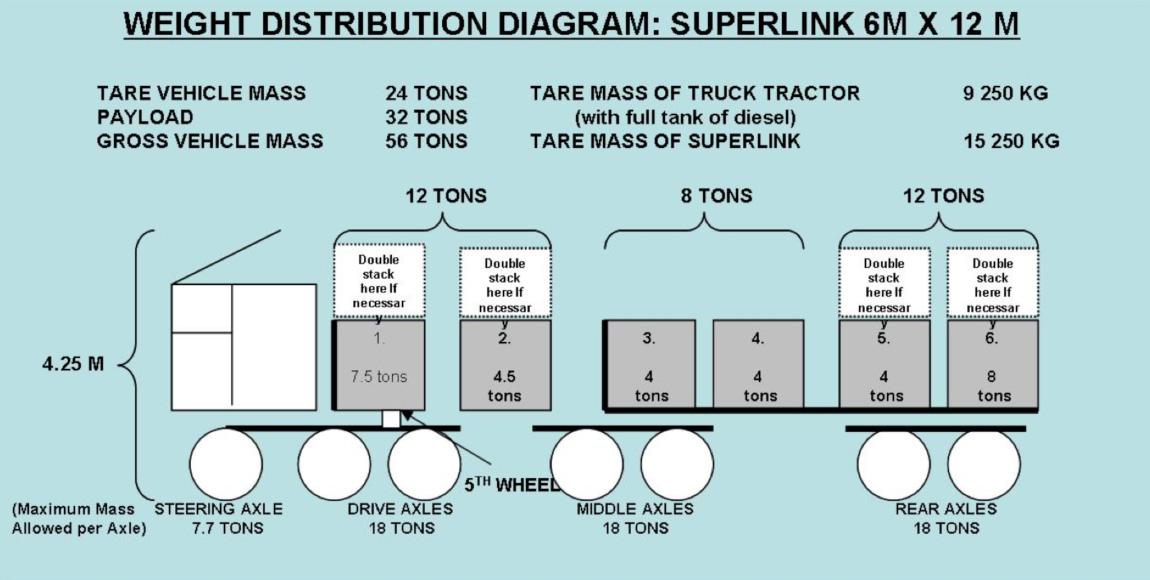

Loading a 6 x 12 m superlink rig:

• Start loading on the front of the back trailer with cargo that meets the weight requirements, but is not able to be double stacked. (Positions 3 and 4 as indicated in the Weight Distribution Diagram).

• Load heaviest base cargo at the back of the back trailer and against the headboard of the front trailer. (Positions 1 and 6 in the Weight Distribution Diagram).

• Fill in positions 2 and 5 with the heaviest base cargo.

• Double stack positions 1, 2, 5 and 6 if necessary, still maintaining the weight limits as indicated in the Weight Distribution Diagram.

Warning

Never load the back trailer and not the front trailer. This creates a see-saw effect that could cause the truck tractor and front trailer to lift when braking.

Important information:

Payload 32 t

Gross vehicle mass 56 t

Tare mass of horse

(with full diesel) 9 250 kg

Tare mass of trailer 15 250 kg

Maximum height allowed 4,3 m

Inside height of container 2,5 m

Inside height of tautliner 2,7 m

Inside width of trailer 2,45 m

Maximum load width allowed 2,6 m

Total length of tractor

and trailer 22 m

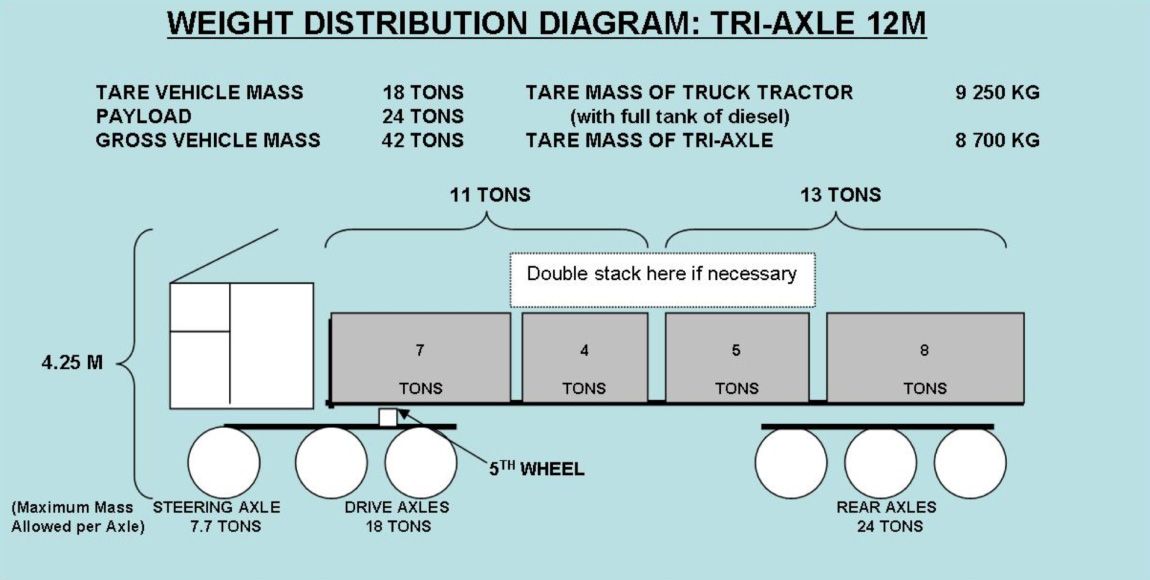

Loading a 12 m tri-axle rig:

• Start loading the heaviest base cargo over the kingpin and tri-axles. Fill in with other base cargo.

• If double stacking is necessary, start at the centre of the trailer, using the position of the centre twist locks as a starting point. Load forwards and backwards from this point, keeping the load as even as possible on each side of the starting point. Do not exceed the maximum weights as indicated on the Weight Distribution Diagram.

Important information:

Tare vehicle mass 18 t

Payload 24 t

Gross vehicle mass 42 t

Tare mass of horse

(with full diesel) 9 250 kg

Tare mass of trailer 8 700 kg

Maximum height allowed 4,3 m

Inside height of container 2,5 m

Inside height of tautliner 2,7 m

Inside width of trailer 2,45 m Maximum load width allowed 2,6 m

Total length of tractor

and trailer 18,5 m

Securing the Load

• Blocking and bracing with lumber or other materials must be used to secure, protect and prevent the load from shifting on route. Lumber used must be free of nails and splinters in order to not damage bags and parcels being transported.

• Ensure twist locks are in the locked position when transporting containers.

• Make sure there are enough straps, that they are in good condition and strong enough to hold the load/prevent it from shifting. Never tie knots in cargo straps.

• A minimum of eight cargo straps with four-tonne breaking strength each is the requirement on a superlink with a 32-t payload.

• Cargo straps must be secured to the vehicle’s load anchorage points and not its dropsides.

• Use corner plates to prevent damage to the cargo when tightening straps.

• Use short-link chains rather than long-link chains; they fit more snugly around the corners of square loads and will ensure a tighter and safer securement of the cargo.

• Nylon rope will fray around metal corners and therefore requires a rubber tube to be slipped over it at points of contact.

• Tarpaulins are for waterproofing, not securing. Nets are for holding the shape of the load. Straps are for securing the load.

Warning

All loads must be tarped and netted (flow bins and drums need only be netted).

Published by

Mike Fitzmaurice

One Comment

Leave a comment Cancel reply

focusmagsa

how does the registration work is the vehicles [trucks] is still under finance at FNB Bank? Do we need to register them at the Traffic Offices again? It is only for coal and grain products that we want to move to Mozambique/Botswana and Zimbabwe?